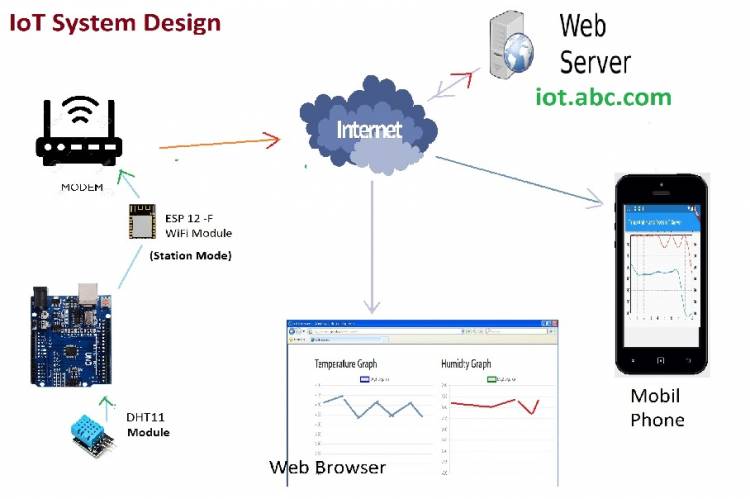

IoT System Design 1 Temperature and Humidity Monitoring System Circuit Diagram Each component plays a crucial role in ensuring that manufacturing operations remain optimized, scalable, and responsive. Below are the key components that make up GPS IoT-enabled manufacturing systems: GPS Sensors and Tracking Devices. At the heart of any GPS IoT-enabled manufacturing system are GPS sensors and tracking devices. These devices Benefits of machine monitoring. Smart machines are the basis of industrial IoT and the key to competitive advantage for any manufacturing plant. Some of the benefits of the industrial equipment monitoring as the first step to achieving industry 4.0 status are: Efficiency in all steps of the manufacturing process; Reduced waste;

Sensor technology advancements in the era of the smart factory and industry 4.0 has been utilized to measure the conditions and parameters of manufacturing process such as temperature, humidity, and other environmental conditions in smart factories [17].Also, IoT sensors in smart factories can be applied to monitor the entire manufacturing process, from raw materials to finished products [18].

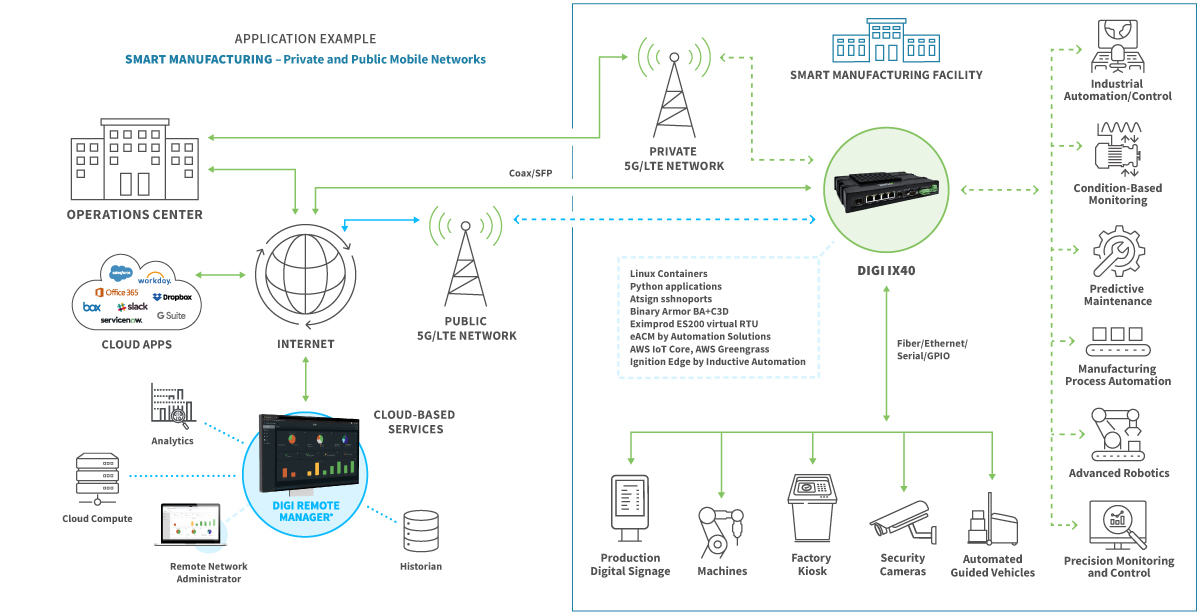

IoT based Smart Factory System Circuit Diagram

A) Understanding IoT and DCS Control Systems for Smart Manufacturing . 1.1 Internet of Things (IoT): The IoT refers to a network of interconnected devices and objects equipped with sensors and software that enable data collection and exchange over the Internet. Within the context of smart manufacturing, IoT devices can be integrated into Before diving into the selection process, it's essential to have a clear understanding of what production monitoring systems are. A production monitoring system (PMS) is a software application that collects and analyzes data from the production process in real-time.These systems are designed to collect, analyze, and visualize data from various stages of the production process.

IoT (Internet of Things) based Smart Factory Systems are revolutionizing the manufacturing industry by enabling greater efficiency, connectivity, and automation. These systems leverage IoT devices, sensors, data analytics, and communication technologies to create a more streamlined and intelligent manufacturing process. The rising cost of energy and the urgent need for sustainability have driven industries to adopt smarter solutions for monitoring and optimizing resource consumption. In this study, we present an Industrial Internet of Things (IIoT)-based approach for real-time energy and air consumption monitoring in manufacturing, focusing on a legacy Turret Punch Press (TPP) at Mitsubishi Electric Air IoT takes manufacturing process efficiency to a whole new level. That's possible through real-time IoT data analytics and collection and machine-to-machine communication. They will scale IoT systems easily and enable remote monitoring and control. Speaking of cloud-based solutions, we've delivered one for our client, a manufacturer of